Ολοκληρωμένες λύσεις στη διαχείριση της συντήρησης

Κάντε τη συντήρηση το ανταγωνιστικό σας πλεονέκτημα, οργανώνοντας την καθημερινότητα των συνεργείων σας και αυξάνοντας την αξιοπιστία των μηχανών σας.

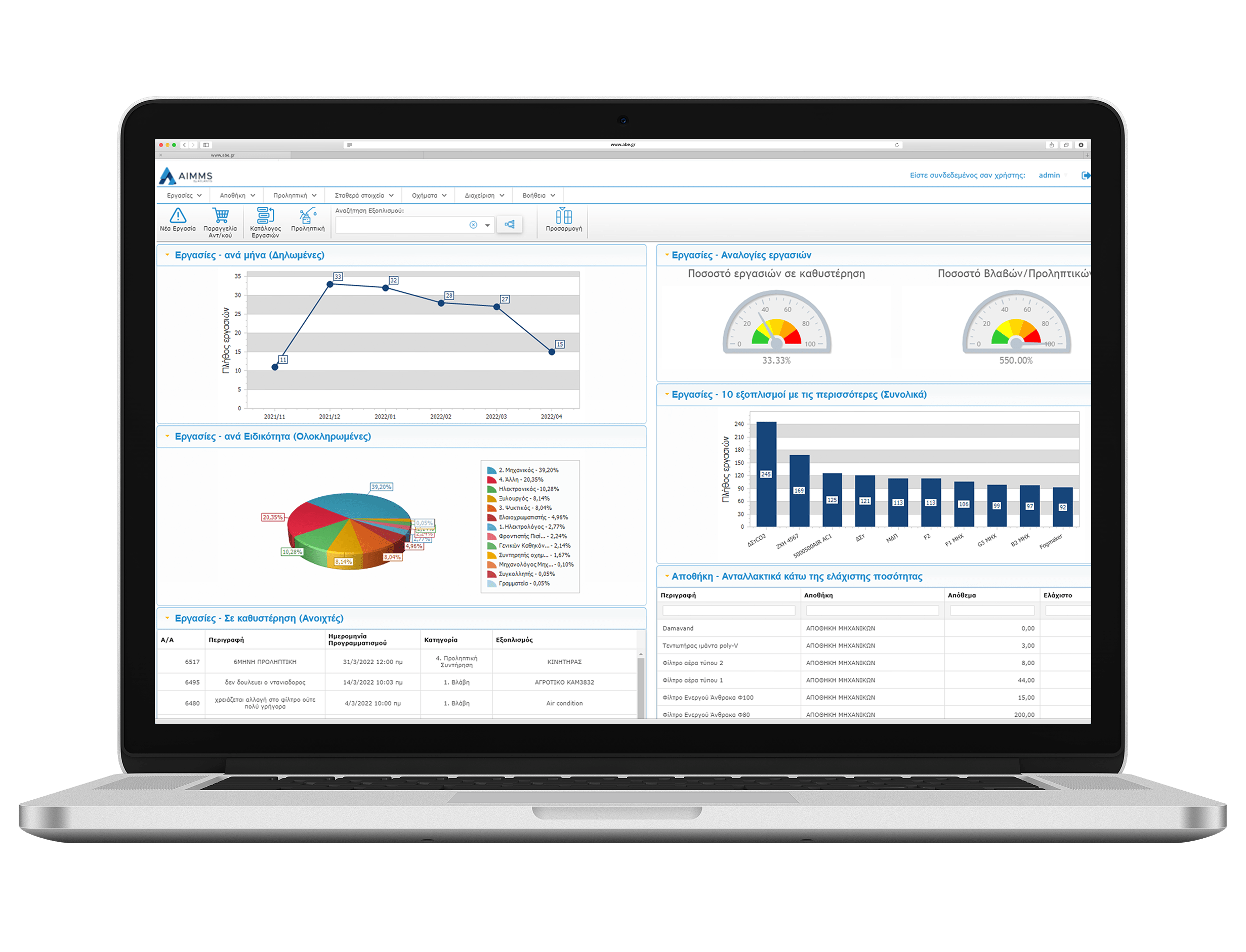

Το CMMS στα ελληνικά

Το AIMMS αποτελεί το αναγκαίο εργαλείο κάθε εταιρίας που επιθυμεί να οργανώσει τις διαδικασίες του τμήματος συντήρησης, να ελαχιστοποιήσει την γραφειοκρατία και κυρίως να συλλέξει τις απαραίτητες πληροφορίες για ένα σύγχρονο και αποτελεσματικό Management.

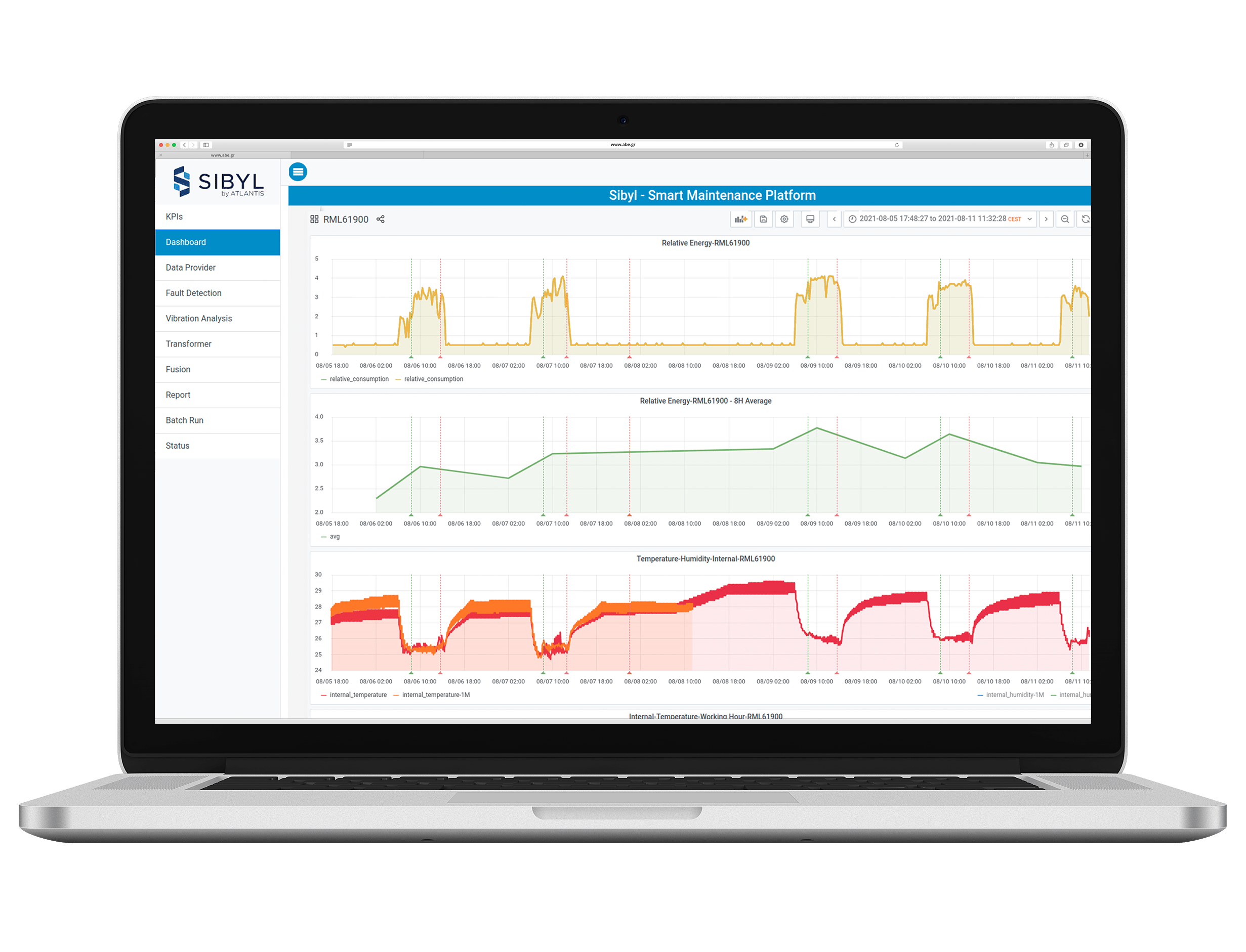

Προβλέψτε το μέλλον των μηχανών σας

To Sibyl αποτελεί μία ολοκληρωμένη λύση για την παρακολούθηση της υγείας του εξοπλισμού. Ενσωματώνοντας αλγορίθμους μηχανικής μάθησης και τεχνολογίες Industry 4.0, συλλέγει και αναλύει σήματα αισθητήρων για τον εντοπισμό, τη διάγνωση ή την πρόγνωση των βλαβών και τον υπολογισμό του υπολειπόμενου χρόνου ζωής του εξοπλισμού.

Total Productive Maintenance

Η ATLANTIS Engineering παρέχει συμβουλευτικές υπηρεσίες για την εφαρμογή του TPM, μιας ολιστικής μεθοδολογίας για την διαμόρφωση σύγχρονης εργασιακής κουλτούρας, φιλοσοφίας διαρκούς βελτίωσης και στην αποτελεσματική αξιοποίηση νέων τεχνολογιών. Το TPM αποτελεί το ασφαλές μονοπάτι για την κατάκτηση του World Class Manufacturing.

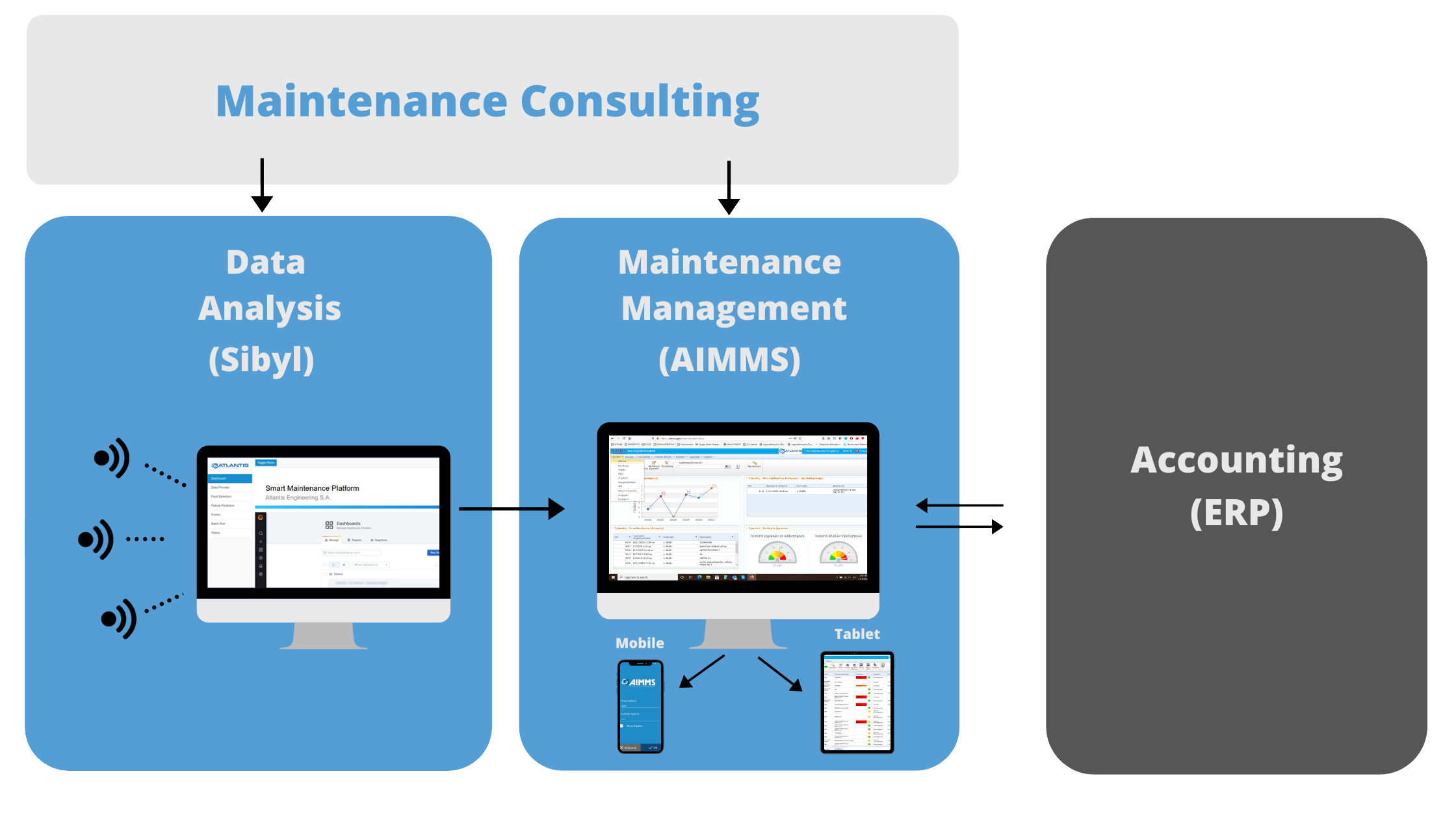

Ολοκληρωμένες λύσεις με το κλειδί στο χέρι

Το AIMMS και το Sibyl σε συνδυασμό με τις συμβουλευτικές υπηρεσίες της ATLANTIS Engineering προσφέρουν μια ολοκληρωμένη λύση και στο πιο απαιτητικό τμήμα συντήρησης. Η διασύνδεση με τρίτες εφαρμογές και η ευέλικτη επικοινωνία με πελάτες και προμηθευτές εξασφαλίζουν τον αυτοματισμό που θα επιθυμούσε κάθε εταιρία.